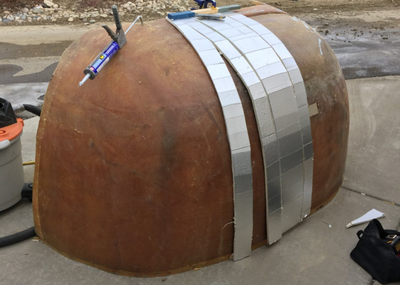

It was 67 degrees today! The meteorologist had been predicting it for a week, so I couldn't miss the opportunity to work on the Airstream. I did what any good teacher would do when they have a fantastic student-teacher at the helm. I took the day off. I've been slowly plinking away at the reflectix insulation. It is not particularly time consuming, or not much more than any other step, but there is a lot of measuring. Basically, I am using industrial contact cement from 3M. (I am a big fan of just about everything 3M makes. Everything that company produces seems to work.) I spray both the inside of the aluminum skin and the backside of the reflectix, wait two minutes, carefully align the piece, and press. The glue holds instantly, but it usually stays workable for a second or two.  With my free day (no kids! no lists! no distractions!) I nearly finished the reflectix. In the pic, you can see the 3M cold weather tape on all of the seams that are not against a beam. I'm not sure if I'm supposed to tape the seams along the beams, but I overlapped the corners with reflectix and they are glued solid. It seems pretty airtight. So I'm skipping it; it would cost at least $100 and take most of a day to foil tape all the reflectix along the metal beams. There is one spot on the opposite end yet to do, along with several panels where I have yet to repair the exterior skin on the side of the trailer. (More to come on that step soon.) Unfortunately, I wasted at least an hour trying unsuccessfully to use foam board to insulate the fiberglass encaps before putting them back on. I wrote last time that I'm using rigid foam board to complete the insulation. I also remember mentioning that I'm terrible at geometry. Hey what is harder to make curve, bubble wrap or rigid foam board?  It actually looks pretty slick in the photos, but the amount of time it took to make four strips of foam was way, way too much. Then every strip would need each seam (both vertical and horizontal) sealed with tape. I figured by the time that was done, it would be more expensive and less warm than just using reflectix on the back of the endcaps. I'll still use the foam board on the rest - all the rest of the interior curves are round in only one direction. I forgot to take a good photo of the reflectix on the endcap above; I have one more to do, so I'll try to remember. BUT this is the milestone: The first original material went back in! I've demolished and tossed, remade pieces, and put in brand-new stuff, but this is the first part that's from 1962 that I took out that I get to replace. I'll need to partly remove it again in order to fish electrical wires behind it, so it is just held up with clecos. But it is in! That floor is calling my name...

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorI'm not an Airstream Jedi, yet. Airstream Jedi would have sounded presumptuous, like I know what I'm doing. That couldn't be further from the truth. Padawan is a title I can hope to live up to. Favorite Links:Knots Per Hour

My friend Mike is building an airplane. Check it out. Archives

August 2018

Categories |

RSS Feed

RSS Feed