0 Comments

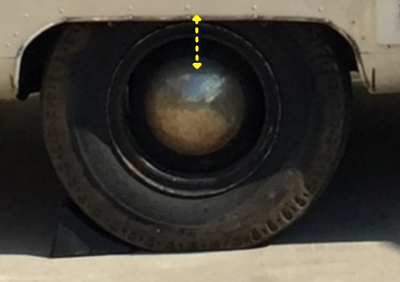

I'm pretty sure I babbled. That's the kind of thing I do when I'm nervous. I was turning over this baby that I've been working on for two years. Babbling is also the exact wrong way to communicate that I know what I'm doing. Awe, hell. I don't know what I'm doing. Eisley had a 55 year old axel. While many things are wonderful about a vintage Airstream, the axel is not one of them. I'm not an axel expert (which was abundantly clear to the folks at Ratco, more on that in a bit), but I understand that torsion axels have internal rubber rods under. The rubber rods flex as the trailer bounces down the road. Over time, however, the flex wears out. The torsion arm then sags and there's no flex in the system. In order to get a new axel, I needed to find someone who makes axels for vintage Airstreams. Fortunately, one of the gurus I mentioned in a previous blog makes brand-new replacements. After a few emails determining exactly what I need, Collin Hyde shipped out an axel. I chose an axel that has a slightly higher clearance, for the tanks and for mountain roads. However, buying the axel was the easy part. The old axel was welded on, so it needed to be cut off with precision. Next, a new mounting plate needed to be made so that the new axel has the right thing to mount onto. Third, the mounting plates needed to be welded onto Eisley. If the rest of it wasn't tricky, this is the step that gave me shivers. If the plates are welded even fractions-of-an-inch incorrectly, the alignment would be off. If the alignment is off, then the trailer pulls down the road cockeyed. Tires wear out quickly, gas milage is off, extra stress on the tow vehicle, etc. Finally, the axel gets bolted on. Suffice to say, this one was beyond my skills. So I had the axel shipped to Ratco, a local axel repair shop. Locally, they are very well known as the best in the business. Several people told me, "If you have an axel job; they're the best." Despite their high reputation, I was a bit of a nervous wreck. They were professional and cordial, but I kinda had the impression that they were hearing my instructions much like I hear parent suggestions for my classroom. They smiled and nodded and then disregarded most of what I said. Fortunately, it's pretty clear they know their business better than me. (My sorry-but-not-sorry apologies to any parent offended...) When they called the next day, I was sure they were about to tell me about some problem (that's my story for all repairs on Eisley). Instead, they said I could come pick it up. Eisley was ready to roll. When I picked Eisley up, they wanted me to know that Airstream was 3/4" off when it built the frame. If I noticed a slight difference in where each wheel sits inside its own wheel well, it was because Airstream got it wrong, they hadn't. Ratco uses a laser to measure very precisely each side of the axel to the hitch, to get the alignment perfect. One wheel well is fractionally closer to the hitch than the other. So there is an appearance that one wheel is further forward than the other, but in reality the are precisely aligned. To be honest, I can't see it. I love that kind of precision and it certainly gives me piece of mind. Perhaps the easiest way to see the difference between the old axel and the new axel is where the wheel sits in the wheel well in the old and new system: I'm a little behind in my writing, Eisley's been home for almost a month and I've been working on the floor, split-rim wheels, shocks, and trim. Next time.

|

AuthorI'm not an Airstream Jedi, yet. Airstream Jedi would have sounded presumptuous, like I know what I'm doing. That couldn't be further from the truth. Padawan is a title I can hope to live up to. Favorite Links:Knots Per Hour

My friend Mike is building an airplane. Check it out. Archives

August 2018

Categories |

RSS Feed

RSS Feed